How Zato helped SATO Vicinity successfully deliver a custom app with multiple software integrations

SATO Vicinity develops and sells products that use its global-standard PJM RFID (Phase Jitter Modulation Radio Frequency Identification) technology to track and identify tagged items. Uniquely, PJM RFID can quickly identify large amounts of tagged items with 100% accuracy, even when randomly or tightly packed. A subsidiary of electronics manufacturer SATO Global, SATO Vicinity builds high-end, customized applications for customers worldwide from industries including healthcare, blood and pathology, and wholesale diamonds.

The challenge

Developing a custom tagging app requiring several software integrations.SATO Vicinity was asked by orthopedic implant manufacturer LimaCorporate (Enovis) to develop an automated solution for tagging items into its inventory, using PJM RFID. LimaCorporate makes artificial replacements for joints, bones, or cartilage, for clients around the globe.

Typically, LimaCorporate's clients order large batches of implants in multiple sizes, as they don't know exactly what size will be needed until during surgery. Labeling and tracking each implant correctly is vital to prevent mistakes. But manually checking and labeling each new implant was slow, error-prone, and limited the scalability of the production process.

With thousands of implants built daily, LimaCorporate needed a faster, more accurate way to log each new implant into its inventory management system. They chose PJM RFID as it is the only RFID tagging solution that is unaffected by the radiation sterilization used during LimaCorporate's manufacturing process.

As well as supplying PJM RFID tags, readers, and printers, SATO Vicinity needed to develop a bespoke tagging application - an automated solution for registering each new implant in LimaCorporate's existing systems.

To achieve this, SATO Vicinity knew the tagging application would need to communicate with several different databases, as well as to its RFID readers. But SATO Vicinity didn't have the in-house capabilities to easily build the complex arrangement of multiple software integrations required.

The solution

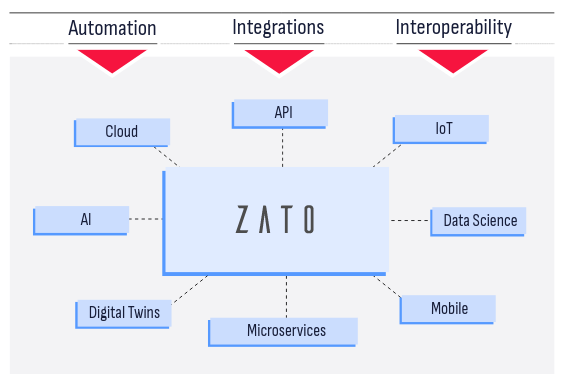

The Zato platform makes it easy to connect to multiple databases and RFID readers.SATO Vicinity turned to Zato Source, who had previously helped develop SATO's innovative platform PJM Global, which connects RFID readers to applications anywhere.

The tagging application needed to connect to the RFID readers, communicate with three databases - in MongoDB, Microsoft SQL, and Oracle - and listen for a particular file type from LimaCorpo- rate's ERP system. SATO Vicinity and Zato Source worked together to build all of these connections and workflows in Zato software, plus a web-based user interface. Zato Source implemented all the various integrations required.

"We chose to build the application with Zato Source because the Zato platform makes it easy to connect to multiple databases, and it was a natural fit to communicate with our PJM Global platform. These were key requirements for the tagging application."

How the new solution works

As each implant is built, it is put in a box alongside an encoded RFID tag. The tag draws on data which the tagging application automatically pulls from the ERP system, detailing which implants are about to be manufactured.When Orbit 2 rolled out, how much difference did existing Orbit users notice? Very little - which in this instance, was a marker of success. Everything is working smoothly, meaning no disruption to Orbit users' business operations.

The boxes of implants pass through an RFID reader on a conveyor belt and the reader sends information about each one to the tagging application. When this happens, the tagging application automatically:

- Adds information on each new implant to the tagging application database (via the integration with MongoDB)

- Registers each new implant in the inventory management system (via the integration with Oracle)

- Logs each new implant in Orbit 2, a specialist logistics management app (via the integration with Microsoft SQL)

LimaCorporate staff can access and manage data on what's happening via the custom user interface, which always has up-to-date information thanks to the Zato integrations. The tagging application is also set up to automatically send emails to alert staff to any issues occurring.

The outcome

Greater efficiency, productivity, and accuracy in adding items to inventory.The new automated tagging system has streamlined LimaCorporate's workflows around adding items into its inventory. Implants are tagged much faster, manual errors eliminated, and staff productivity has increased as they are freed up from manually tagging and logging items.

"Because we're using RFID and Zato, the tagging application automates all of what used to be a very slow manual process. So now you have a conveyor belt with lots of items traveling on it, automatically registering these implants into multiple different databases without any human intervention."

Automating the tagging and associated data updates across multiple systems has increased LimaCorporate's operational efficiencies. PJM RFID-tagged items can easily be tracked from end to end of the supply chain, without the need for retagging or manual processing.

And because the tagging application integrates with LimaCorporate's inventory and logistics management systems, staff have peace of mind that data about the implants is always accurate and up to date.

"We've had good feedback on the new system. LimaCorporate are happy with it and they're looking at expanding the use of RFID in other areas of the business."